Comprehensive guide to floor insulation

Floor insulation is often overlooked with more focus typically placed on insulating walls and roofs. After all, if heat rises, how much impact can the floor really have on keeping us warm?

U-value Calculator

Start your U-value calculation

David Milner

David Milner

Comprehensive guide to floor insulation

Floor insulation is often overlooked with more focus typically placed on insulating walls and roofs. After all, if heat rises, how much impact can the floor really have on keeping us warm? In this blog, we explore the crucial role of floor insulation and how it effectively contributes to:

- Sustainability – reducing carbon emissions

- Finances – helping to lower heating bills

- Health – enhancing thermal comfort

We will also explore the best methods for insulating various floor constructions in both new and existing buildings to comply with building regulations. Additionally, we will evaluate the durability, flexibility, and thermal performance of different floor insulation types.

How does floor insulation support sustainability?

Sustainability covers a wide range of factors, but one of the most impactful ways buildings can contribute to a greener future is by helping to reduce carbon emissions. Floor insulation plays a crucial yet often overlooked role in this effort. While walls account for around approximately 35% of heat loss and roofs approximately 25%, floors can contribute up to 15%. Proper insulation helps minimise this loss, significantly improving energy efficiency, helping to reduce a buildings overall environmental impact.

Floor insulation was not a building regulation until the mid-1990s. However, with the UK’s goal of achieving net zero carbon by 2050, every aspect of heat loss, including floors, are now under increased scrutiny. Installing floor insulation with reliable thermal performance is essential in helping to reduce emissions in both new residential and commercial buildings.

Floor insulation also helps to improve the sustainability of existing buildings by addressing a common source of heat loss. Many older buildings have uninsulated suspended timber floors, which can lead to significant energy waste. Properly insulating these floors helps reduce heat loss and lower carbon emissions across the UK’s housing stock.

David Milner, Technical Team Leader at Celotex, emphasises the importance of floor insulation: "The Celotex technical team is receiving an increasing number of enquiries about floor insulation. Our customers recognise its significant contribution to carbon reduction and energy efficiency. As regulations tighten, we provide both the products and technical expertise needed to help the industry find the right floor insulation for their projects."

How does floor insulation choice affect sustainability?

The type of insulation used can notably influence the environmental sustainability of a construction project.

Natural insulation materials such as sheep’s wool, hemp and wood fibre may appeal to those seeking sustainable options, as they typically have a lower manufacturing energy demand compared to products such as stone wool and glass wool.

On the other hand, chemical-based insulation materials including PIR, Phenolic, EPS and XPS, are not naturally occurring but can offer lower lambda values. This means less material is required to achieve the same level of insulation helping to offset their higher energy-intensive production.

The choice of insulation material also depends on the type of floor. Flexible insulation offers more natural options when installed between floor joists in a suspended timber floor. However, for applications beneath concrete screed, where compressive strength is essential , natural options are more limited.

The sustainability of insulation is a complex matter, factoring in the energy used during manufacturing, the energy savings after installation, and its overall embodied carbon. For large projects, specifiers may use sustainability assessment tools to compare insulation products directly, while smaller refurbishments are often influenced by customer preferences for natural materials.

Can floor insulation improve thermal comfort?

Yes, floor insulation plays a key role in enhancing thermal comfort in heated spaces. For most people, when the temperature difference between our head and ankles exceeds 2°C, we feel uncomfortable, often leading people to turn up the thermostat. If the floor feels cold, people instinctively increase heating levels.

By insulating the floor, temperatures remain more consistent throughout the space, reducing the need for extra heating. This not only improves comfort but also helps lower energy bills, increase overall efficiency, and save money.

What types of floor insulation are available?

A variety of insulation options are suitable for floors, generally categorised into two main types: rigid and flexible insulation.

What is flexible insulation and where is it best suited?

Flexible insulation has low compressive strength, making it ideal for applications where it does not need to bear weight, such as insulating between the joists of suspended timber floors.

All types rely on trapped air for insulation, with their effectiveness measured by the lambda value, the lower the lambda, the better the insulation performance. A product with a lower lambda doesn’t need to be as thick as one with a higher lambda to achieve the same level of thermal performance, known as the floors ‘U-value’. In other words, using a lower lambda product optimises the thermal performance of the available space, resulting in the best possible U-value for the floor.

All these products are classified as ‘vapour open,’ meaning they allow moisture to pass through and are often referred to as ‘breathable’ insulation. This makes them a popular choice for older properties, where the building fabric has traditionally allowed moisture to escape. When correctly specified and installed, vapour open insulation may help manage moisture movement in older properties, potentially reducing the risk of condensation within the building fabric.

The table below lists common types of flexible insulation with their typical lambda values. For precise performance details, always refer to the full product specifications provided by the manufacturer.

| Type | Flexible or rigid? | Typical Lambda (W/mk) | Trapped gas? | Compressive strength | Vapour open or closed? |

| Stone wool | Flexible | 0.032 to 0.044 | Air | low | Open |

| Glass wool | Flexible | 0.032 to 0.044 | Air | low | Open |

| Sheep's wool | Flexible | 0.033 to 0.038 | Air | low | Open |

| Hemp | Flexible | 0.040 | Air | low | Open |

| Wood fibre | Flexible | 0.036 to 0.038 | Air | low | Open |

What is rigid insulation and where is it best suited?

Rigid insulation has a higher compressive strength, making it suitable for supporting floor loads when used to insulate concrete floors. In this case, insulation with a closed-cell structure is preferred as it offers better resistance to vapour and moisture penetration from the ground.

For this reason, PIR, Phenolic, and XPS are commonly specified for floor insulation. The precise compressive strength needed to support the floor load of a project must be calculated by a structural engineer.

In cases of extremely high loads, cellular glass insulation may be preferred due to its very high compressive strength compared to the other options. Millions of sealed glass cells within the cellular glass insulation make it exceptionally strong, as well as water and vapour proof. However, since it does not use a blowing agent, its thermal performance is generally lower than other insulation alternatives, meaning a thicker floor build-up may be required to achieve the same U-value.

The lambda value of floor insulation boards is a key factor in their specification as higher performance insulation can provide thinner solutions, potentially reducing excavation depth and installation time. Similar to the flexible insulation table, the values provided here are typical, and exact product details should always be confirmed with the product manufacturer.

Product data is something David is passionate about: “We offer both XPS and PIR products for floor insulation, making sure all the key specification data is readily available. Our technical team supports this product information and is always available to help our customers make an informed decision on the best insulation board for their project.”

| Type | Flexible or rigid | Typical Lambda (W/mk) | Trapped gas? | Compressive strength | Vapour open or closed? |

| Wood fibre | Rigid | 0.036 to 0.038 | Air | 150 | Open |

| PIR | Rigid | 0.021 to 0.028 | Blowing agent | 120 to 150 |

Closed |

| Phenolic | Rigid | 0.019 to 0.021 | Blowing agent | 120 to 150 | Closed |

| EPS | Rigid | 0.032 to 0.040 | Air | 70 to 250 | Varied - check with manufacturer |

| XPS | Rigid | 0.029 to 0.036 | Blowing agent | 500 to 700 | Closed |

| Cellular glass | Rigid | 0.036 to 0.055 | Carbon dioxide | 600 to 2400 | Closed |

What key properties should you consider for floor insulation specification?

Now that we’ve explored both flexible and rigid floor insulation options, let’s take a closer look at their key properties to determine their suitability for specific flooring applications.

Why is compressive strength a consideration for floor insulation?

When insulating areas where load bearing is required, such as installing insulation beneath or above a concrete slab, selecting insulation with sufficient compressive strength is essential. Rigid boards like PIR, Phenolic, and XPS are best suited for these applications.

A structural engineer should assess the expected floor loading to determine the necessary compressive strength of the insulation. XPS typically offers higher compressive strengths than PIR and Phenolic, making it a more suitable choice for high-load applications such as industrial floors.

Why is thermal performance a consideration for floor insulation?

Each type of insulation has a different thermal conductivity, known as its lambda value, measured in W/mK. A lower thermal conductivity indicates better performance, as it slows heat transfer through the insulation layer. Rigid boards with closed-cell structures, such as PIR, Phenolic, and XPS offer generally provide better thermal performance per unit thickness compared to flexible insulation, which typically has an open structure.

A floors thermal performance is measured by its U-value in W/m2K, with lower values indicating better insulation. The overall U-value depends on the floor’s size and shape, which determines its P/A ratio, the ratio of the floor’s perimeter to its area. This ratio, combined with the insulation’s lambda value, helps calculate the insulation thickness required to achieve the desired thermal performance.

Why is durability a consideration for floor insulation?

Floor insulation must be durable enough to withstand structural loads and potential moisture exposure, which can arise from surrounding ground conditions, flooding, or leaks from heating systems.

Open-structured insulation materials, such as mineral wool, can absorb water, potentially reducing their thermal performance and structural integrity over time. While EPS insulation has a partially closed-cell structure, it is more permeable than fully closed-cell alternatives and can absorb some moisture, which may affect its long-term durability.

PIR and Phenolic insulation although closed cell, should not be exposed to moisture and are typically installed above a damp proof membrane (DPM) to prevent water ingress. For applications requiring direct ground contact or high moisture resistance, XPS insulation is generally preferred due to its improved water resistance and structural stability.

Why is flexibility a consideration for floor insulation?

When insulating suspended timber floors in existing buildings, the flexibility of the insulation affects ease of installation. Mineral fibre insulation can readily compress and pushed between floor joists, making installation straightforward. Rigid boards can also be used, but they require precise cutting to achieve a tight ‘friction-fit’ between the joists. While this may take longer, using rigid boards such as PIR and Phenolic of the same thickness with lower thermal conductivity result in improved thermal performance and a lower U-value for the floor.

Why is acoustic performance a requirement for separating floor insulation?

In separating and internal floors, insulation is primarily used for acoustic purposes rather than thermal improvement. This is common in apartment buildings, where the floor of one dwelling serves as the ceiling of another. While thermal insulation is not necessary as these are both heated spaces. Acoustically insulating the floor helps reduce airborne noise transmission, creating a quieter and a more pleasant indoor environment. Flexible insulation materials such as mineral fibre, sheep’s wool and hemp provide good sound absorption and noise reduction.

How do I insulate a suspended timber floor?

Suspended timber floors are commonly found in older buildings. They typically consist of timber joists spanning between bearing walls, with their ends supported by wall plates. These floors can contribute to heat loss in two key ways:

- Insufficient or missing floor insulation allows heat to escape through the floor, reducing energy efficiency.

- Draughts from gaps between floorboards and around room perimeters provide an additional path for convective heat loss.

Properly insulating a suspended timber floor helps address both paths of heat loss.

As with any insulation retrofit, it’s essential to ensure that work does not negatively impact the existing fabric of the building.

Below are key considerations to factor in when insulating a suspended timber floor.

What are the required U-values for floor insulation?

In England, Wales, and Northern Ireland, retrofitting an existing suspended timber floor the notional target requires a U-value of at least 0.25 W/m2K.

For new thermal elements added to an existing building, the notional required U-value improves to 0.18 W/m2K. In Scotland, the typical target U-value permitted for both cases is stricter at 0.15 W/m2K.

Building control may allow adjustments where achieving the U-value is not technically feasible, so it’s always advisable to check requirements prior to starting the work.

Insulation manufacturers can provide U-value calculations based on the exact floor build-up, ensuring the most suitable insulation type and installation method is specified to meet regulatory requirements.

David highlights the importance of obtaining accurate U-value calculations:

“Accurate U-value calculations are essential for demonstrating compliance with building regulations, as they contribute to overall energy efficiency assessments. Our online U-value calculator allows customers to explore different insulation options, thicknesses, and build-ups. Additionally, the Celotex technical team can provide tailored U-value calculations and recommendations for various flooring applications.”

Why should you assess the floor condition and determine the ventilation needs?

Before installing insulation, thoroughly inspect the condition of the floor and the void beneath. Check the joists and floorboards for any signs of damage, rot, dampness or infestation. Adequate ventilation is essential for suspended timber floors to prevent moisture buildup, so ensure vents or airbricks are free from damage or blockages. When fitting insulation, take care not to obstruct existing ventilation paths.

How do you select and install the right floor insulation?

Both flexible insulation, such as rock wool and glass wool, and rigid insulation, like PIR, can be specified to achieve the required U-value. The necessary thickness will depend on the insulations lambda value, with lower lambda materials requiring less depth to meet performance targets.

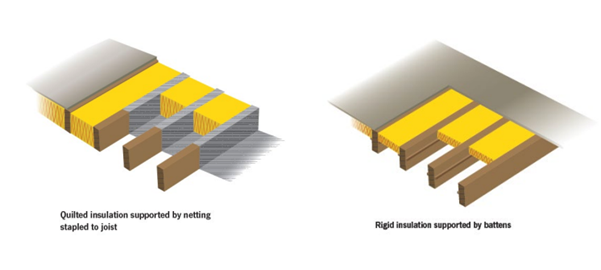

Install the insulation so that its full thickness remains consistent across the entire span width between the joists. Support for flexible insulation can be achieved using a board, battens, or durable mesh beneath the joists. Rigid boards may be secured by resting them on battens attached to the sides of the joists and secured in place with nails driven into the joists.

Moisture control barriers may be necessary if there is a risk of condensation. It is important to ensure that adding insulation does not create cold bridges within the floor, as these could lead to an increased risk of condensation build-up, potentially causing long-term damage.

For more detailed information, refer to the government’s “Guide to Best Practice” for retrofitting floor insulation in suspended timber floors.

What are the potential savings from retrofitting floor insulation in an existing home?

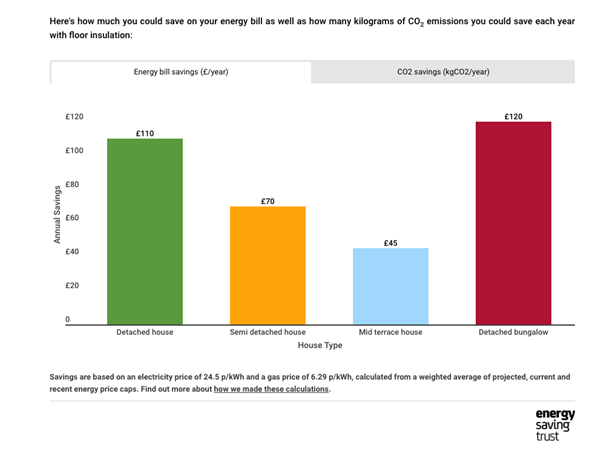

The potential savings from installing floor insulation depends on the property type and existing thermal performance before the upgrade. The Energy Saving Trust has provided estimates for four different house types, offering a useful indication of possible energy bill reductions1:

| House type | Energy Bill savings (£/year) |

| Detached house | £110 |

| Semi-detached house | £70 |

| Mid terrace house | £45 |

| Detached bungalow | £120 |

1https://energysavingtrust.org.uk/advice/floor-insulation/

What is the best thermal insulation for use with concrete floors?

When insulating a concrete floor, rigid insulation boards made from PIR, Phenolic, or XPS are the most suitable options due to their compressive strength, which enables them to withstand floor loadings. Additionally, the excellent thermal performance of PIR and Phenolic helps minimise the overall floor build-up thickness. XPS provides both high compressive strength and moisture resistance for applications with exceptionally high loads or when used below the damp proof course. Cellular glass insulation also offers an alternative due to its superior strength, however, its higher lambda value and higher cost make it a less cost-effective option when compared to XPS.

For new concrete floors the typical installation process for PIR, Phenolic, or XPS insulation includes:

1. Laying a damp proof membrane (DPM) either above or below the concrete slab.

2. Placing insulation boards above the DPM, either

- Above the concrete slab, or

- Below the concrete slab

3. Installing an air and vapour control layer (AVCL) over the insulation.

4. Applying a concrete screed to insulation installed above the slab and installing the final floor finish once the screed has cured.

PIR, Phenolic, and XPS insulation boards can also be used to insulate an existing concrete floor. However, adding insulation increases floor height, which may require adjustments to deck thresholds, skirting boards, doors and ceiling heights. An alternative method , though requiring significant structural work and cost considerations, is to remove the existing floor and install a fully insulated concrete floor in its place.

Is floor insulation compatible with underfloor heating (UFH)?

Yes, PIR, Phenolic and XPS rigid floor insulation boards are ideal for use with underfloor heating (UFH). The pipes are clipped onto the fixing system above the AVCL and insulation. The floor screed is then poured on top. As the floor insulation sits underneath the pipes it ensures that the heat is directed upwards into the room and limits the loss of heat into the ground below. The floor screed heats up and acts as a giant radiator giving even distribution of heat across the room.

UFH is a popular choice in modern new-build properties, especially when combined with heat pumps. The increased surface area of heat radiation suits the lower flow temperatures supplied by the renewable heat pump technology.

Where can I find out more about floor insulation solutions?

At Celotex we have several XPS and PIR floor insulation solutions that are suitable for a wide range of domestic and commercial applications. Celotex provides technical support, including U-value calculations, and project consultations.

David Milner explains Celotex’s floor insulation offer: “By offering both XPS and PIR flooring insulation, Celotex can help match insulation solutions to specific project needs. We can assist in selecting insulation boards to align with or exceed the performance requirements of different flooring applications.”

Have questions about flooring insulation? Contact our experienced team with the details of your project to discuss how we can help.